Hotline

Vietnamese

Vietnamese  English

English  Laos

Laos  Cambodia

Cambodia  Thailand

Thailand  Indonesia

Indonesia  Philipins

Philipins  Myanmar

Myanmar

VADGF 2500 PRESSURE FILLING MACHINE

Contact

Pressure filling machine VADGF 2500 with capacity of 2500 bottles / h

- Capacity: 2500 Bottles / h

- 6 automatic stages

- Standard: ISO 9001:2015

- Origin: Genuine

- Warranty 12 months

- Free shipping-installation

Buy now

Free shipping

Request a consultation

Build your own plan

Order, advice 0949.41.41.41 - 0943.41.41.41 (7:30 - 21:00)

Category: FILLING-VADGF

Product code: VADGF 2500

- Describe

- Parameters, configuration

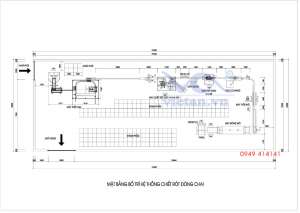

- Picture

Product details

PET bottle filling machine, Pressure filling machine VADGF2500 with 6 automatic stages is genuine, ISO 9001:2015 standard.

The machine is modernly designed, dedicated to filling carbonated drinks into bottles according to the high-pressure principle of 2500 bottles per hour. Model VADGF2500 is one of the most modern filling lines currently supplied and installed by Viet An. This is the solution to produce carbonated soft drinks with high capacity and automatic.

VADGF2500 is designed with automatic air conveyors to put bottles into the washing machine, filling, capping 3 in 1 in a short time, automatically rinsing, filling, capping, automatically putting the bottle cap to the capping unit when inadequate, stop supply the cap when full caps and detect the strange object in the bottle.

PET bottle filling machine is suitable for all facilities producing carbonated plastic bottled water in all provinces of the country and overseas factories.

Collective photo of Viet An company

Carbonated water bottle filling machine VADGF2500 is manufactured at Viet An's factory or imported directly from the US, Italy and Taiwan, China.

With the desire to improve labour productivity in the direction of automation, increasing competitiveness, the use of a 6-in-1 filling machine VADGF2500 provided by Viet An is the most reasonable choice for customers.

6 in 1 pressure-filling machine VADGF2500 is necessary for the production

Carbonated soft drinks became popular in everyday life, many people chose to use. To create this special water, the filling is a very important step in the production process.

Coca water, Pepsi, juice, lemon juice, beer, fresh beer ... they are all produced by modern filling lines, different from the normal filling principles.

Carbonated drinks have become favourite drinks not only for children but also for young people and the elderly. When demand is high, it means that manufacturers will have to expand their scale, improve technology, invest in the installation of modern machinery and equipment that can operate automatically to minimize the presence of workers in the production process that labour productivity increased.

6 automatic stages are integrated into a PET bottle filling machine VADGF2500 that will meet the above requirements of customers.

The whole process of manufacturing and assembling VADGF2500 pressure-regulating machines meets ISO 9001:2015 standard.

The difference of the pressure filling machine VADGF2500

- Production standards: ISO 9001:2015

- The most modern filling technology of the United States

- Dedicated pressure filling line, integrating 6 automatic stages

- Quick filling, the amount of carbonated water is filled accurately, not overflowing, no leakage

- The close capping head is made of steel and plated with a stainless steel layer of high quality 304 material. Using the magnetic force, perform the function of taking the cap, screwing cap adjustable, do not damage the bottle cap and tighten firmly.

- Smart control panel with PLC display screen. Can adjust the capacity, the level of carbonated solution. Automatically disconnects when there is no bottle

- The machine works stably for a long time

- Can fill PET bottles 350ml, 500ml, 1500ml

6 automatic stages of automatic pressure filling machine VADGF2500 at Việt An

Stage1: Air conveyors AC2

This is a transport system for PET bottles, which cannot be missing in today's bottled water production plants. Conveyor system helps to replace workers, increase productivity, improve work efficiency. When the air conveyor operates, just need a worker standing in front of the conveyor is required to put the bottle shell into the air conveyor. Then the air conveyor will automatically cornered the bottle together and put the bottle shell to the next stage of the 3 in 1 pressure filling machine VADGF2500.

Stage 2 + 3 + 4: Rinse wash-filling- 3 in 1 bottle capping

With integrated design 3 capable of washing, filling and capping in a machine, creating a closed, uniform operation process. The machine has 14 wash heads, 12 filling heads and 4 close caping heads. Operating capacity is equal to 4-5 employees.

Principle of filling: Pressure pressure filling

On this 3 in 1 machine, there is a control panel system with many features to start the machine, set the operation mode, set capacity quickly or slowly, set the norm of carbonated solution into bottles... All parameters after installation will be displayed on the PLC screen for operators to easily observe and monitor.

The water container, the frame and many other components made from stainless steel 304 give the machine a more beautiful look, easy to clean and can be used for a long time. The special point of this model is that you can customize the bottle size, bottle height. That will create a variety for production.

Stage 5: bottle cap loading machine

This is a very smart device, using sensors to identify the bottle caps face up or face down. The face-up caps will be put on the production line, the face-down cap will be dropped. Help save time and cost. This type of machine is necessary for the process of producing carbonated soft drinks, brewing ...

Stage 6. light inspection

It is very important to evaluate the quality of carbonated water bottles. This contributes to the prestige of the brand produced with consumers. Light inspection can see strange objects in bottles. Employees need to follow up to exclude non-standard products.

Automatic stages purchase separately (Optional)

In addition to the 6 automatic steps required to purchase the pressure filling machine VADGF2500, you can invest to buy some other machines such as:

1. Bottle loading and bottles arrange machine

The work of transport bottles and sorting bottles requires 3-4 participants. On average, you have to pay about 7 million VND /person/month. So every month you will lose about 21 to 28 million. Now with this Bottle loading and bottles arrange machine you don't need to use the workers. The machine can automatically load and arrange bottles for you. You only need to put the plastic bottle shell into the tray containing the bottle shell of the machine. Other stages will operate automatically. Maximum capacity of 4000 bottles per hour. Bottle loading and bottles arrange machine are designed to operate continuously with high performance. Help businesses achieve high efficiency in production.

specifications of the machine

|

Model |

VALS4000 |

|

Machine capacity (BPH) |

2000-4000 |

|

Bottle type - 2 moulds (ml) |

300-1500 |

|

Electrical capacity (kW / h) |

0.75 |

|

Size (D * R * C mm) |

1200X1500X900 |

|

Weight / kg) |

150 |

|

Price (USD) |

5900 |

- CO2 prickle machine

The machine is designed to bring CO2 gas straight into the bottle without foaming. With the gas content from 1: 3-1: 10, the machine is designed modernly, easy to use. Absolute accuracy with durability over 10 years.

Specifications of CO2 prickle machine

|

CO2 prickle machine |

Model |

VAHS2000 |

|

Capacity (bottle / h, log 24 bottles of 500ml) |

1500-10000 |

|

|

Gas content (CO2H2O in volume) |

1:3-1:10 |

|

|

Water content (CO2H2O) |

>3.0 |

|

|

Input temperature of cold water (degree c) |

3 đến 5 |

|

|

Pressure (Mpa) |

0.5-0.9 |

|

|

Electrical capacity (kW / h) |

2 đến 10 |

|

|

Size (D * R * C mm) |

2200*1800*2100 |

|

|

Price (USD) |

39900 |

Viet An is a supplier of 6-in-1 automatic PET water bottle filling machine

Viet An General Trading Joint Stock Company, the top 100 leading enterprises in the country. With outstanding achievements in contributing to the market of the most modern machines such as high pressure filling machine, pure water filling machine, water filtration line and high-capacity ice cube making machine. The products that Viet An provides are genuine products with perfect warranty and maintenance services.

Continuously updating new technologies, Viet An has been affirming its position in the domestic and regional Asian markets. Viet An commits to all customers about the quality of goods we provide. To be grateful to customers who have trusted to use the products of filling machine, water filter line, industrial ice making machine ... that Viet An has launched on the market for nearly 20 years, Viet An has launched the program 100% free shipping and free installation apply nationwide.

Notes when installing

Need to ensure the installation ground reaches a minimum area. During the production process, regularly clean the machine according to the instructions. Conduct periodic inspection of the machine. The process of changing the bottle mould must ensure proper technique according to the instructions

See more article details

Specifications of pressure filling machine VADGF2500

A. PET CARBONATED BOTTLE FILLING MACHINE VADGF2500 - 6 STAGES MUST BE BUYED

|

Model |

VADGF2500 |

|

Wash head |

14 |

|

Extraction head |

12 |

|

Head swirled |

4 |

|

Machine capacity (350ml bottle / h) |

2500 |

|

Machine capacity (500ml bottle / h) |

2500 |

|

Machine capacity (1500ml bottle / h) |

1000 |

|

Power capacity (kw/h) |

2 |

|

Pressure (Mpa) |

0.4-0.6 |

|

Bottle size (mm) |

Tuỳ chỉnh |

|

Bottle height |

Tuỳ chỉnh |

|

Electricity supply |

Tuỳ chỉnh |

|

3 in 1 size (D*R*Cmm) |

2050*1650*2250 |

|

Weight (Kg) |

2400 |

|

Air conveyor |

2000 |

|

Bottle cap loading machine (D * R * Cmm) |

1200*950*3000 |

|

light inspection (D*R*Cmm) |

600*200*1000 |

|

Plastic conveyor (D*R*Cmm) |

2000 |

|

Price (USD) |

|

B. SEPARATE PURCHASE STAGE INTEGRATED INTO A 6 IN 1 CARBONATED WATER FILLING MACHINE- VACGF2000

|

Model |

Price (USD) |

|

1. Bottle loading and bottles arrange machine - VALS4000 |

Contact |

|

2. CO2 prickle machine - VAHS2000 |

Contact |

Hỏi đáp & đánh giá VADGF 2500 PRESSURE FILLING MACHINE

0 đánh giá và hỏi đáp

Bạn có vấn đề cần tư vấn?

Gửi câu hỏi