Hotline

Vietnamese

Vietnamese  English

English  Laos

Laos  Cambodia

Cambodia  Thailand

Thailand  Indonesia

Indonesia  Philipins

Philipins  Myanmar

Myanmar

VAQGF450 3 in 1 Automatic Bottle Filling Machine

Contact

3 in 1 Automatic bottle filling machine VAQGF450

- Capacity: 450 bottles with 20 liters per hour

- Origin: Genuine

- Warranty 12 months

- Free shipping-installation nationwide

Buy now

Free shipping

Request a consultation

Build your own plan

Order, advice 0949.41.41.41 - 0943.41.41.41 (7:30 - 21:00)

Category: FILLING-VAQGF

Product code: VAQGF 450

- Describe

- Parameters, configuration

- Picture

Product details

VAQGF 450 automatic 3-in-1 bottle filling machine with the new technology in 2021. As one of the products that have been chosen by many pure drinking water business units.

This specialized product for filling and bottling is Viet An General Trading Joint Stock Company - a leading enterprise in importing and distributing water purification line equipment and filling machine in Vietnam. imported from abroad.

Applying the most modern technology of the United States, the filling machine with absolute precision, this product has satisfied a lot of customers in the bottling and bottled beverage business in Vietnam.

VAQGF 450 3-in-1 automatic bottle filling machine applies the most advanced modern technology from the United States

For automatic 3-in-1 bottle filling machine VAQGF 450 Việt An, we promise that the product is a genuine imported product with full certification. Machines are assembled in Shanghai - China from components imported from the United States according to ISO 9001:2015 standards are considered to be the most rigorous today.

Compact industrial design, 100% material made of 304 stainless steel. VAQGF 450 automatic 3-in-1 bottle filling machine looks beautiful and has a longer use time, requires less maintenance, and runs smoothly and smoothly. No cost of the home of business units. With 3 automatic stages to ensure the process of filling bottles quickly, accurately, ensuring food hygiene and safety requirements of the Ministry of Health about bottled drinking water.

Viet An supplies all kinds of 3 in 1 bottle filling machines nationwide with full capacity to meet the needs of many customers. Good products combined with perfect service quality will surely satisfy customers when using Viet An filling machine.

3 automatic stages of filling machine VAQGF 450

VAQGF 450 automatic bottle filling machine is integrated 3 functions to operate automatically in one machine. Businesses do not take up much installation space, do not need much labor for the production of bottled drinking water 20L.

Stage 1: Wash in and out of bottles automatically:

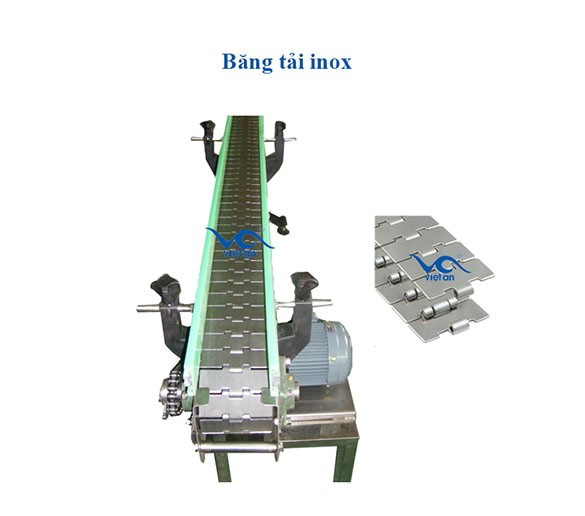

Structure: Chain conveyor, bottle holder, conveyor motor, 304 stainless steel head pressure pump.

Empty 20L jars without a caps are transferred to the loading by the worker and placed on the bottle holder face down. The chain conveyor will move the shells clockwise by the operation of the conveyor motor. 304 stainless steel head pump has the function of pumping pure water and sterilized ozone inside the bottle, outside the bottle. The 20L jar will be washed clean inside and out, then conveyed by a conveyor chain to the filling unit.

Stage 2: Pour pure water into a 20L container

The 20 L bottles after being cleaned inside and outside clean in stage 1 will be transferred to the filling heads. VAQGF450 model with 3 filling heads, is connected to the pure water through a pipeline system. Under the piston thrust, purified water is filled by 3 filling heads into 3 water bottles. The filled water bottles will be transferred to the bottle capping part in stage 3.

Stage 3: Automatic close capping jar

VAQGF450 model with a capping head design is connected to the cap tray system through the cap duct system. The jar caps will be poured into the tray by the worker and taken to the top of the cap by the cap duct. This capping head is made of 304 stainless steel, using the piston's thrust to close the cap to the jar at a speed of 450 lids / h.

The closed 20L jar will be pushed out by the hydraulic cylinder to the next stage

To operate the 3 automatic stages of washing inside and outside the bottle, pouring water into the bottle and closing the 20L bottle cap is an intelligent control system mounted on the VAQGF450 body. This control system can automatically operate the entire washing, extraction and capping process according to a pre-programmed program. More specifically, the system has the ability to automatically disconnect when there is an incident, making the production of bottled drinking water much safer than other conventional filling machines on the market.

With 3 automatic stages integrated into VAQGF450 filling machine, this will help businesses save the cost of hiring 3 - 5 labor workers while ensuring labor efficiency.

Besides this 3-in-1 machine, Viet An also supplies many other types of machines for the production of bottled water and bottles. If you are interested, you can refer to here

Advantages of 3-in-1 automatic bottle filling VAQGF 450

When applying the 3-in-1 automatic bottle filling machine, VAQGF 450 will bring many outstanding advantages such as:

1.Intelligent control system: With modern design but easy to use, customers can easily adjust the operating speed of the automatic filling machine VAQGF450

- Accuracy: Our products use the rotary encoder to fill with higher accuracy

- Filling speed: The product is designed to change the frequency to adjust the filling speed. The filling speed is adjustable via the control panel.

4.High strength: This is the most advanced line of filling machine today. All components are genuine imported products with a service life of more than 20 years

With the ability to operate fully automatically and self-contained. The system of 3-in-1 automatic filling and filling machine VAQGF 450 of Viet An will ensure your business the following issues:

Helps achieve high productivity of 450 bottles/hour

Product quality is guaranteed

Saving (production time, labor → reducing production investment costs)

Increase the competitiveness of enterprise products

Demonstrate a professional working style

Branding for your unit.

Integrated automatic purchase stage for VAQGF450 bottle filling machine (optional)

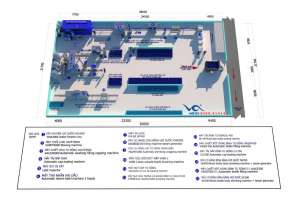

Viet An always leapfrogs, constantly improve and update the latest technology in the world. With the desire to help businesses producing bottled water at home and abroad with modern production lines, automatically bring high efficiency. In addition to providing the market of 3 in 1 automatic bottle filling machines, Viet An also provides other types of automatic machines for customers to integrate with the 3 in 1 machine to create a Fully automatic filling line. Here are some suggestions for customers to refer to installation investment

- BS-1 semi-automatic decapping machine BG-600.

With a compact industrial design, does not take up space. Applying the most advanced USA technology of cap retraction, the BG-600 cap dispenser can easily separate the lid from the bottle in a snap. The cap after being separated from the bottle is not deformed, so it can be reused => saving money

BG-600 cap dispensers are designed with 1 cap retracting device, using piston thrust to pull the cap with a pressure of 0.6-0.8 Mpa. Capacity to remove the cap of the machine from 300-600 cap / h

Specifications of BG-600 automatic decapping machine

|

Model |

BG-600 |

|

Capacity (jar / h) |

300-600 |

|

Wash head |

1 |

|

Electricity supply |

Use Air |

|

Pressure (Mpa) |

0.6-0.8 |

|

Dimensions (LxWxH) |

500x750x1800 |

|

Weight / kg) |

48 |

|

Price (USD) |

|

- ST-600 Automatic bottle washing machine

The external washing machine ST-600 is a great suggestion for customers. With the ability to wash bottles automatically, the machine has 5 wash heads, 5 bottle brushes so it will help businesses save a lot of labor costs. The washing capacity can reach up to 600 bottles / h

This machine is suitable for washing 20L cylinders after use. You can use the RO membrane wastewater to supply the ST-600 automatic bottle washing machine to save water.

Specifications of ST-600 Automatic bottle washing machine

|

Model |

ST-600 |

|

Capacity (jar/h) |

450-600 |

|

Wash head |

5 |

|

Power (kw) |

1.2-1.5 |

|

Pressure (Mpa) |

0.7-0.8 |

|

Dimensions (LxWxH) |

1850x1100x1800 |

|

Weight / kg) |

230 |

|

Price (USD) |

|

- BL-450 automatic bottle loading machine:

Automatic jar loading machine 20L with 3 loading heads. The use of scoured jar load to the position of rinsing pure ozone water in 3-in-1 filling machine VAQGF450 to ensure sterilization and removal of dirt in the jar shells. With a capacity of 450 jars / h.

Specifications of BL-450 automatic bottle loading machine:

|

Model |

BL-450 |

|

Capacity (jar/h) |

450 |

|

Wash head |

3 |

|

Power (kw) |

0.75 |

|

Dimensions (LxWxH) |

1350x960x1200 |

|

Weight / kg) |

90 |

|

Price (USD) |

|

- Automatic cap loading machine CL-1200:

Uses: Automatically cap the machine when it is not, and stop filling the cap when it is full in the cap duct. 100% guaranteed without The cap is inverted

Workers just need to fill the lid on the tray of the loading machine, the machine will automatically bring the cover to the cap duct system of the 3-in-1 flask of the VAQGF450 thanks to the conveyor motor system operating the conveyor.

Specifications of CL-1200 Automatic cap loading machine

|

Model |

CL-1200 |

|

Capacity (lid / h) |

300-1200 |

|

Power (kw) |

0.18 |

|

Dimensions (LxWxH) |

600*600*3000 |

|

Weight / kg) |

65 |

|

Price (USD) |

|

5. Light inspection (DJ-100)

The purpose of the DJ-100 is to detect probabilities. In the process of producing bottled pure water, the manufacturer needs to ensure the quality of the water bottles produces. Therefore, customers can invest in installing this DJ-100 light inspection to scan the probability of a bottle at the rate of 5-10% produced.

With the structure of 2 lights placed in the lamp holder, when the water jar was filled and capped at 3-in-1 filling machine VAQGF450 and conveyed by stainless steel conveyor through this light inspection, workers will Observe whether the jar has any abnormalities

Specifications of DJ-100 light inspection

|

Model |

DJ-100 |

|

Power (w) |

3 x 20w |

|

Dimensions (DxRxCmm) |

600x200x1000 |

|

Price (USD) |

|

- Shrinking machine steam generator (SK-450)

The machine uses the heat of steam to shrink the membrane to make the body shrink beautifully, without wrinkles. Fast shrinkage rate

The machine is designed to have 1 boiler and 1 shrinkage chamber.

Membrane chamber is made of stainless steel suitable for wet environments. Easy to clean, durable over 15 years

Specifications of SK-450 Shrinking machine steam generator

|

Model |

SK-450 |

|

Capacity (lid / h) |

400-450 |

|

Power (kw) |

24 |

|

Dimensions (LxWxH) |

1500x550x800 |

|

Price (USD) |

|

- SK-450E heat bottle shrinking machine

In addition to the jar shrinkage machine, Viet An also supplies heat shrink film shrinking machines. The machine uses heat to shrink the polymer film over the entire body. With special design, the temperature in the shrinking chamber is kept to a certain degree, so that the shrink film is always smooth, beautiful and wrinkle-free.

Specifications of Shrinking machine steam generator (SK-450)

|

Model |

SK-450E |

|

Capacity (jar / h) |

400-450 |

|

Power(kw) |

24 |

|

Size (DxRxCmm) |

1500x550x800 |

|

Price (USD) |

|

- Plastic conveyor for empty jars CSG-6.

The saving of labor costs involved in production and business activities is very necessary for the era of automation today. These plastic conveyors will help you do not need labor to move the jar from one stage to another. When the conveyor motor operates, the empty cylinders will be moved from one position to another quickly, saving a lot of installation space.

Technical specifications of Plastic conveyor for empty jars CSG-6

|

Model |

CSG-6 |

|

Power(kw) |

0.55 |

|

Size (DxRxCmm) |

6000x290 |

|

Price (USD) |

|

9. Stainless steel conveyor CSSG-5:

The use of stainless steel conveyor is to transport the filled bottles filled with water automatically, without labor. This will help businesses reduce production costs, increase competitiveness

Specifications of CSSG-5 Stainless steel conveyor

|

Model |

CSSG-5 |

|

Power(kw) |

0.75 |

|

Size (DxRxCmm) |

5000x290 |

|

Price (USD) |

|

- 5G decapping-rinse and remove cap machine BS-2

This is a machine used to remove and wash bottles. Only for 69 million VND but will help you remove the cap from the bottle quickly with 2 drawers and a bottle cleaning chamber.

At this price, it will be suitable for all businesses producing bottled water today

Specifications of 5G decapping-rinse and remove cap machine BS-2

|

Model |

BS-2 |

|

Power(kw) |

1.9 |

|

Size (DxRxCmm) |

770x1250x1150 |

|

Price (USD) |

|

Customer service of Viet An:

With a product warranty period of 1 year and a lifetime of product maintenance. Viet An also has leading engineers with long experience in manufacturing and manufacturing machinery that will advise customers to get the most perfect choice for them.

With the purpose of bringing the benefits to customers, Viet An commits that customers will be able to use the technology 3-in-1 automatic bottle filling machine VAQGF 450 and enjoy the incentives.

See more article details

Specifications of 3 in 1 Automatic jar filling machine VAQGF450

- 20l JAR FILLING MACHINE VAQGF450 – 3 STAGES MUST BE BUYED

|

Model |

VAQGF450 |

|

Extraction head |

250-300 |

|

Head swirled |

3 |

|

Power capacity (kw/h) |

10 |

|

Pressure (Mpa) |

0.8-1.0 |

|

size (D*R*Cmm) |

4600x1950x2110 |

|

Weight (Kg) |

1100 |

|

Feature |

Water heating to 60 ° C |

|

Price (USD) |

|

- SEPARATE PURCHASE STAGE INTEGRATED INTO A 3 IN 1 JAR FILLING MACHINE VAQGF450

|

Model |

Price (USD) |

|

1. BG-600 automatic cap decapping machine |

|

|

2. ST-600 Automatic bottle washing machine |

|

|

3. BL-450 Automatic jar loading machine |

|

|

4. CL-1200 Automatic cap loading |

|

|

5. DJ-100 light inspection |

|

|

6. SK-450 Shrinking machine steam generator |

|

|

7. SK-450E heat bottle shrinking machine |

|

|

8. CSG-6 plastic conveyor |

|

|

9. CSSG-5 Stainless steel conveyor for water tank containing |

|

|

10. 5G decapping-rinse and remove cap machine BS-2 |

|

Hỏi đáp & đánh giá VAQGF450 3 in 1 Automatic Bottle Filling Machine

0 đánh giá và hỏi đáp

Bạn có vấn đề cần tư vấn?

Gửi câu hỏi