Hotline

Vietnamese

Vietnamese  English

English  Laos

Laos  Cambodia

Cambodia  Thailand

Thailand  Indonesia

Indonesia  Philipins

Philipins  Myanmar

Myanmar

12000-6 IN 1 AUTOMATIC BOTTLE FILLING MACHINE-VACGF12000

Contact

6-in-1 automatic bottle filling machine VACGF 12000 capacity of 12000 bottles / h

- Model: VACGF12000

- Capacity: 12000 bottles/h

- 6 automatic stages

- 1-year warranty

- Maintenance: Long-term

- Standard: ISO 9001:2015

- Free shipping-installation nationwide

Buy now

Free shipping

Request a consultation

Build your own plan

Order, advice 0949.41.41.41 - 0943.41.41.41 (7:30 - 21:00)

Category: FILLING-VACGF

Product code: VACGF12000

- Describe

- Parameters, configuration

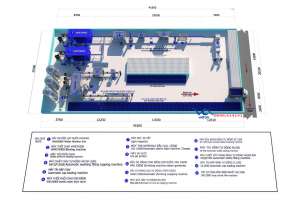

- Picture

Product details

6-in-1 automatic bottle filling machine VACGF12000 is the most popular bottle filling machine in 2021. With many technical improvements, upgrading of the filling, washing and swirling technology has helped to improve the filling efficiency to 12000 bottles of 500ml / h.

With the 6-in-1 bottle filling, rinsing and washing machine VACGF12000, you will get high economic efficiency, saving the cost of rent from 12-15 workers.

Model VACGF12000 is suitable for filling all kinds of pure water, mineral water, electrolyte, fruit juice ... into PET plastic bottles in factories and manufacturing enterprises.

With the design mostly by stainless steel material SUS 304, VACGF12000 is highly resistant to corrosion, uninfected electromagnetic, withstand the wet environment, absolute safety.

VACGF12000 is manufactured at Viet An's factory or imported directly from the US, Italy, Taiwan, China. According to the latest technology in the United States. This is a suitable product for large-scale drinking water plants

Let's join Viet An to learn more about this line of 6 in 1 automatic bottle filling machine VACGF12000 through the following article.

VACGF12000 automatic bottle filling machine supplied by Viet An

VACGF12000 is researched and produced by a team of leading engineers in the field of filling and quantifying water. With a sophisticated design, both aesthetically and highly productive.

Viet An products are supplied and installed at home and abroad with preferential prices and long-term warranty and maintenance services. Free shipping-installation.

Viet An- The automatic filling machine supplier in Vietnam

Viet An General Trading Joint Stock Company, called Viet An for short, was equitized from August 2009. Being a leading company in the field of import, distribution of bottle filling machines, automatic bottle filling with all kinds of capacity from 2000 bottles to 24000 bottles of 500ml per hour and from 100 to 1200 bottles of 20 litres/ hour.

In addition, Viet An is also a leader in importing, distributing and installing industrial water filtration lines, bottle blowing machines, jar blowing machines and manufacturing ice cubes making machines.

Always focus on the quality of products we provide, constantly improve and improve service quality to protect the interests of customers. For nearly 20 years of construction and maturity, Viet An has achieved great achievements recognized by the party, State awarded and consumers voted.

Outstanding features of 6-in-1 automatic bottle filling machine VACGF12000 of Viet An

- Automatic wash bottles quickly with a capacity of 12,000 bottles per hour

- Extraction of water into the bottle quickly, accurately, fuel-efficient, high capacity 12000 bottles / h

- capping the bottle quickly, evenly and beautifully with a capacity of 12,000 caps per hour

- Automatic loading the bottle cap for the screwing process quickly and efficiently

- Check the stranger object correctly and quickly

- Equipped with a variety of bottle clamps, can use a variety of PET bottle sizes such as 350ml, 500ml, 1500ml

- Automatic production capacity is fast up to 12,000 bottles per hour

- Can replace 10-15 employees to help businesses reduce a large amount of hiring costs

6-in-1 automatic PET bottle filling machine VACGF12000 is the perfect choice for every manufacturer

While the demand for bottled water increases exponentially due to population growth and economic development, people's living standards are improved. It is necessary to expand the production scale and increase productivity to meet market demand.

With semi-automatic bottle filling machine that can only produce small productivity, that needs many workers due to the high price difficult to compete. Not to mention, it is difficult to ensure absolute food safety and hygiene factor.

So how can we reduce production costs to the lowest level without changing labour productivity?

To solve this problem, the 6-in-1 automatic washing filling and swirling machine VACGF12000 will help ensure labour efficiency and reduce production costs.

VACGF12000 automatic bottle filling machine is designed to operate continuously for a long time.

Model VACGF12000 works equivalent to 12-15 workers. When installing and using the VACGF12000 bottle filling machine, you will save rental costs from 12-15 works. With the current salary of about 7 million VND / person / 1 month, you can save from 84 to 105 million VND / month.

Automatic bottle filling machine according to ISO 9001:2015

Viet An always focuses on the quality of products that we provide. So all types of automatic bottle filling machines including washing machine, filling, swirling automatic bottle cap 6 in 1 VACGF12000 which Viet An marketed are genuine. With the production and assembly process of ISO 9001:2015 international standard.

The machine works stably, high durability, less maintenance, warranty. Operation is less noise-generating

6 automatic stages of automatic bottle filling machine VACGF12000

Stage1: Air conveyors AC2

This is an extremely important stage in the filling line.

It is composed of a frame system of 304 stainless steel with a shiny surface, easy to clean and safe to use.

Use AC 2 gas to move the bottle automatically and quickly. gather bottles together without deforming bottles

Stage 2 + 3 + 4: Rinse wash-filling- 3 in 1 bottle capping

+Automatic Rinse the bottle

Upgraded and improved in size, the washing unit in the VACGF12000 bottle filling machine is equipped with 24 wash heads, so the labour productivity is much higher than other conventional washing machines.

Bottle clamping unit, gears, rotating shaft of the washing machine are made of SUS304 stainless steel material to help the machine to operate stably, without rusty, long life.

It is possible to change the Mold set of each corresponding type of bottle to carry out washing of different types of bottles.

Fast bottle washing speed. The washing heads operate with gas pressure, the force pushes water into the bottle to wash quickly, strong to help wash, the washing capacity is higher.

+ Automatic filling

In order to be compatible with the bottle washing unit, this filling section is also designed to contain 24 filling heads.

The bottle clamps are also designed flexibly, can be replaced to extract many sizes of bottles

With stainless steel material of spindle, bottle clamp, filling head helps ensure hygiene safety for the filling process.

The filling heads are all attached to the induction unit so it can be filled according to the specified norms when installing the machine. The filling speed can also be adjusted quickly and slowly. Maximum extraction capacity is 12000 bottles of 500ml / h

+ Automatic bottle capping:

To ensure the output, the screw part in the VACGF12000 bottle filling machine is equipped with 8 screw heads. The machine screw cap is fast, accurate and fully automatic.

And the bottle clamping part of the cap screw machine is also designed flexibly to create a variety in production. Various types of bottles can be used with different volumes

Stage 5: bottle cap loading machine

With fast washing, filling and swirling speeds of up to 12,000 bottles per hour, VACGF12000 is integrated with bottle cap loading machines. The machine can load all kinds of plastic bottle caps for high-speed, automatic screw-cap.

Cap loading machine is designed as delicate and smart. With conveyor motor system automatically corrects the bottle cap when inverted to ensure 100% of air blowing in is correct.

The system of the magic eye is automatically inserted cap when missing and when cap full is automatically disconnected. The system helps the operator easier during use.

Stage 6. light inspection

It is one of 6 automatic stages integrated into VACGF12000 automatic bottle filling machine of Viet An.

With the function of detecting and warning strange objects in bottles of finished products to ensure the production process is up to standard.

Plastic conveyor

To move the bottle from one location to another without wasting time or space, the VACGF12000 is equipped with an air conveyor system and plastic conveyor.

These are the 6 automatic steps of VACGF12000 automatic bottle filling machine required to purchase. To produce bottled water, it has not stopped at these 6 stages. So if you want to replace all workers with modern machines, you can invest in buying more automatic steps below.

Automatic stages purchase separately (Optional)

1. Bottle loading and bottles arrange machine

With the ability to load and arrange many types of bottles, high capacity from 7000 to 10000 bottles per hour. Maximum can reach 12000 bottles per hour. This line is suitable for modern production facilities today.

It can be used for bottles of 350ml, 500ml, 1500ml

Specification of Bottle loading and bottles arrange machine

|

Model |

VALP10000 |

|

Machine capacity (BPH) |

7000-10000 |

|

Bottle type-2 mould (ml) |

300-1500 |

|

Electrical capacity (kW / h) |

1.5 |

|

Size (D * R * C mm) |

2200X2600X2500 |

|

Weight / kg) |

1800 |

|

Price (USD) |

|

2. Bottle dry blow machine -AD12000:

With a weight is about 190kg, the capacity blows from 4,000 to 12,000 bottles per hour. The machine helps remove all the water vapour remaining in the bottle before putting it into packaging

Specifications of the Bottle dry blow machine VAD12000

|

Model |

VAD12000 |

|

Machine capacity (bottle/h) |

4000-8000 |

|

Electrical capacity (kW/h) |

6 |

|

Size (D*R*Cmm) |

1370*800*1500 |

|

Weight (Kg) |

190 |

|

Price (USD) |

|

- 2-head label drop machine-VAL15000:

2-head label drop machine

Drop capacity 9000-15000 labels per hour. The machine can drop labels of size 30-250mm

The most modern label drop technology application machine in the United States

With two head of drop labels, the drop capacity is much higher than the usual one-head drop models.

The ability to drop with high capacity labels, automatic that helps the production of bottled water highly effective. No need for many workers. Accuracy is 99.9%

Easy to operate, easy change label drop capacity

Parameter of Double-head label drop machine

|

Model |

VAL15000 |

|

Capacity (bottle / h) |

9000-15000 |

|

Electrical capacity (kW / h) |

5 |

|

Suitable bottle diameter (mm) |

Φ28-Φ125 |

|

Suitable label length (mm) |

30-250 |

|

Suitable label thickness (mm) |

0.03-0.13 |

|

Suitable internal diameter |

5"-10" |

|

Size (D * R * C mm) |

3900*1200*2100 |

|

Weight / kg) |

750 |

|

Price (USD) |

|

4. Automatic rotary labelling machine to label the round bottle with opp label and hot melt glue: VAR15000.

Automatic rotary labelling machine for labelling round bottles and hot melt glue

Specifications of Automatic rotary labelling machine for labelling round bottles and hot melt glue

|

Model |

VAR15000 |

|

Capacity (bottle / h) |

9000-15000 |

|

Suitable bottle diameter (mm) |

Φ28-Φ125 |

|

Suitable label length (mm) |

30-250 |

|

Suitable label thickness (mm) |

0.03-0.13 |

|

Suitable internal diameter |

5"-10" |

|

Size (D * R * C mm) |

2400*2300*2100 |

|

Weight / kg) |

1,200 |

|

Price (USD) |

5. Steam bottle shrinking machine: VAS15000

Steam bottle shrinking machine

Uses: Use steam to shrink the film into the bottle

The machine consists of a boiler, steam pipe and shrinks chamber. The machine is usually placed at the position behind the label drop machine and the bottle blowing dry machine.

Technical specifications of Steam bottle shrinking machine

|

Model |

VAS15000 |

|

Capacity (bottle / h) |

10000-15000 |

|

Electrical capacity (kW / h) |

24 |

|

Size (D * R * C mm) |

1800*500*1700 |

|

Weight / kg) |

150 |

|

Price (USD) |

|

- Inkjet printer

The print technology expiry date on bottles with print speed 22,000 bottles per hour

It can print up to 3 lines.

Quality ink beautiful, sharp, high capacity

Inkjet printer parameters

|

Model |

VA22000 |

|

Maximum print line |

3 |

|

Electricity supply |

240V |

|

Size (D * R * C mm) |

400*320*527 |

|

Weight / kg) |

27 |

|

Price (USD) |

|

7. Automatic log shrinkage machine: VAGM10000

Application of automatic film shrinking technology to replace many workers

The machine includes a shrinking chamber, conveyor, and frame

You can adjust the mould to shrink log 6 bottles, 12 bottles and 24 bottles easily

Parameter of Automatic log shrinkage machine

|

Model |

VAGM10000 |

|

Capacity (bottle / h, log 24 bottles of 500ml) |

9000-11000 |

|

Electrical capacity (kW / h) |

21 |

|

Size (D * R * C mm) |

5550*3700*2100 |

|

Weight / kg) |

870 |

|

Price (USD) |

|

If you want to invest in a modern and automatic filling machine, please contact Viet An for detailed advice. Hotline: 0949 414141

See more article details

Specifications of automatic filling machine VACGF12000

|

A. VACGF12000 FILLING MACHINE - 6 STAGES MUST BE BUYED |

|

|

Model |

VACGF12000 |

|

Wash head |

24 |

|

Extraction head |

24 |

|

Head swirled |

8 |

|

Machine capacity (350ml bottle / h) |

10000-12000 |

|

Machine capacity (500ml bottle / h) |

10000-12000 |

|

Machine capacity (1500ml bottle / h) |

3500-4000 |

|

Power capacity |

4.5 |

|

Pressure |

0.6-0.8MPA |

|

Bottle size |

Φ55-Φ100 |

|

Bottle height |

100-320 |

|

Electricity supply |

380v-50hz |

|

3 in 1 size |

2800*2200*2400 |

|

Weight |

3500 |

|

Air conveyor |

5000*220*1000 |

|

Bottle cap loading (D*R*Cmm) |

1200*950*3000 |

|

light inspection |

600*200*1000 |

|

Plastic conveyor |

25000*160 |

|

Price (USD) |

|

|

B. SEPARATE PURCHASE STAGE INTEGRATED INTO A 6 IN 1 FILLING MACHINE – VACGF12000 |

|

|

Model |

Price (USD) |

|

1. Bottle loading and arranging machine – VALP10000 |

|

|

2. Bottle blowing machine - VAD12000 |

|

|

3. Double-headed label drop machine – VAL15000 |

|

|

4. Automatic rotary labelling machine for labelling round bottles with opp labels and hot melt glue stick – VAR15000 |

|

|

5. Steam bottle shrink machine – VAS15000 |

|

|

6. Inkjet printer - VA22000 |

|

|

7. Semi-automatic log shrinking machine-VAGM10000 |

|

Hỏi đáp & đánh giá 12000-6 IN 1 AUTOMATIC BOTTLE FILLING MACHINE-VACGF12000

0 đánh giá và hỏi đáp

Bạn có vấn đề cần tư vấn?

Gửi câu hỏi