Hotline

Vietnamese

Vietnamese  English

English  Laos

Laos  Cambodia

Cambodia  Thailand

Thailand  Indonesia

Indonesia  Philipins

Philipins  Myanmar

Myanmar

2000-4 IN 1 AUTOMATIC BOTTLE FILLING MACHINE VACGF2000

Contact

4-in-1 automatic bottle filling machine VACGF 2000 capacity of 2000 bottles / h

- Model: VACGF2000

- Capacity: 2000 bottles/h

- 1-year warranty

- Maintenance: Long-term

- Standard: ISO 9001:2015

- Free shipping-installation nationwide

Buy now

Free shipping

Request a consultation

Build your own plan

Order, advice 0949.41.41.41 - 0943.41.41.41 (7:30 - 21:00)

Category: FILLING-VACGF

Product code: VACGF2000

- Describe

- Parameters, configuration

- Picture

Product details

4-in-1 automatic bottle filling machine VACGF 2000- 4 automatic stages are integrated into one machine, creating automatic high-quality PET bottle filling machine VACGF2000.

The product is capable of filling up to 2000 pet bottles per hour.

The application of science and technology to productive labour is an indispensable need. It decides to increase labour productivity, lower product costs, reduce labour capacity for the worker, improve economic efficiency and product quality.

VACGF2000 automatic washing and filling machine line, capping machine, light inspection is indispensable and very important in bottled water production plants today.

VACGF2000 is being provided by Viet An to domestic and foreign markets. Application of the most advanced technology and combined with high-grade 304 stainless steel materials and production monitoring process according to international standards. The product has a shelf life of over 15 years and is warranted for 12 months.

4-in-1 automatic bottle filling machine VACGF2000 has many outstanding advantages

Belonging to the set of products capable has automatically filling, capping and genuine import of Viet An. Application of the most modern PET bottle filling technology 2021. Products are supplied and installed by Viet An company

With the improvement of technical innovations compared to the previous one, the 4-in-1 automatic bottle filling machine VACGF2000 has been highly appreciated by many domestic and foreign production facilities.

- Provided by Viet An company - Vietnam

Viet An General Trading Joint Stock Company was equitized from August 2021. Being a leading enterprise in importing, distributing filling machines, bottle blowing machines, water filtration lines and producing ice cube making machines.

For nearly 20 years, Viet An has been striving to improve product quality and technical innovation. We always build branding with the quality and trust of customers. Therefore, Viet An has received many noble certificates and awards.

Gold medal for high-quality Vietnamese goods in 2009

Golden Lotus Cup of high-quality Vietnamese goods in 2009

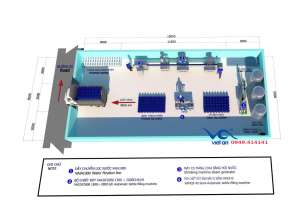

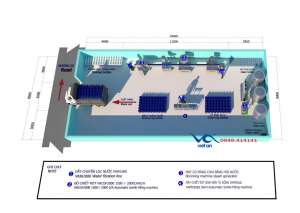

Gold medal for Vietnam's leading brand in 2015

Viet An brand certification achieves ISO 9001:2015 certificate

Best brand in 3 regions in 2017

With countless other noble awards

Especially, in the three consecutive years that Viet An was in the top 100 businesses, it was honoured to receive public announcements and wish the new President Truong Tan Sang, Tran Dai Quang and Nguyen Xuan Phuc.

Viet An is committed to providing the market with quality and reasonable price filling lines to meet the needs of domestic and foreign customers.

- Meets international standard ISO 9001:2015

As one of the most modern automatic filling machines in the market, VACGF2000 applies the most modern production technology of the US with 4 automatic stages to improve efficiency and save labour costs. All production and assembly processes ensure ISO 9001:2015 standards

With an automatic process of washing plastic bottles, bottle filling, light inspection, it helps enterprises meet the requirements of food hygiene and safety of the Ministry of Health.

- No need for many workers

Unlike other semi-automatic filling machine needs requiring many workers. With the VACGF2000 automatic filling machine, you only need 1 worker standing to program and start the machine. The rest of the process of bottle washing, bottle filling and bottle capping take place automatically

- Filling many types of bottles

The production of many types of water bottles with different sizes will meet the diverse needs of users. Unlike older technology extracts, it is only possible to produce a certain type of bottle size such as 250ml, 300ml, 500ml, 1000ml bottles. With a 4-in-1 VACGF2000 bottle filling machine, you can produce a variety of bottles with different volumes. You just need to change the washing-up table shape, the tip of the filling head mould and head swirl cap mould. The time to replace the mould takes about 1 hour. So you can proceed to change the mould after each production shift to ensure capacity as well as working time.

- High capacity

Unlike other semi-automatic filling machines, they have to use a lot of workers which machine capacity is low. Now with the application of advanced science and technology into production and business activities. The 4-in-1 automatic filling machine supplied by Viet An is applied with advanced automatic washing technology with 12 rinse heads, 12 filling heads, 1 capping head and 1 light inspection with only 1 person works equivalent 12 people work.

Who should use the 4-in-1 filling machine VACGF2000 of Viet An

The application of science and technology to production and business activities is an inevitable trend in the era of industrialization and modernization of the country. Using machines to replace human labour has contributed to ensuring productivity as well as reducing product costs, increasing competitiveness for businesses.

Therefore, all water production facilities, producing PET bottles should use this VACGF2000 automatic bottle filling line.

Specifications of 4 in 1 automatic bottle filling machine VACGF2000

Here are 4 automatic steps required for an automatic filling machine VACGF2000.

- Automatic bottle washing

- Automatic bottle filling

- Automatic capping

- Automatic anomalies checking

In the 4 in 1 bottle filling machine, it is also equipped with a plastic conveyor system to transport bottles between automatic stages. In addition to the above 4 required automatic stages, you can equip with additional bottle loading, film shrinking machine. For more details, you can refer to the specifications in the table below.

4 automatic steps required of VACGF2000

Stage 1: Automatic bottle rinse

Empty bottles will be transported to this automatic bottle washing machine. In here, 12 washing head operating with large water pressure, it will automatically spray water into the bottle to wash 2000 plastic bottles in 1 hour. This bottle washing machine replaces 3-5 workers. This is an effective solution to help bottled water production and business units improve productivity while saving labour costs, increasing productivity and increasing competition.

Stage 2: Automatic filling

After the bottle is cleaned with treated water will be transferred to the filling system, with 12 filling heads suitable for plastic bottles. On this system, there will be a speed-adjusting motor to help businesses become more proactive in production. On average, every hour, the machine will pour 2000 bottles of water.

The bottles after being washed will be transferred to the filling machine by the hold bottle mould system. In here, 12 automatic filling heads with a sensor system will pour the water into the bottle according to the installed capacity in the control panel. The filled bottles will be transferred to the bottle capping machine.

Stage 3: Automatic capping

Bottle capping machine with 1 capping head is made of steel and plated with a high grade 304 stainless steel. It is not rust, no corrosion, absolute safety and hygiene. In the top of the capping head attached marbles to hold the bottle cap and capping the PET bottle cap with high speed.

Stage 4: light inspection

On the light inspection attached to a lamp. Stereoscopic lights in the machine have the effect of detecting strange objects in the product. Employees need to follow up to exclude non-standard products. Accuracy up to 99.9%.

Additional buying stages (optional)

- Bottle loading and bottles arrange machine:

Advantage:

- Automatic bottle loading

- Automatic bottle arrange one way

Specification of Bottle loading and bottles arrange machine

|

Model |

VALS4000 |

|

Machine capacity (BPH) |

2000-4000 |

|

Bottle type-2 mould (ml) |

300-1500 |

|

Electrical capacity (kW / h) |

0.75 |

|

Size (D * R * C mm) |

1200X1500X900 |

|

Weight / kg) |

150 |

|

Price (USD) |

|

- Heat film shrinking machine – made in Viet Nam

Heat shrink film machine: consists of 3 main parts: Suction compartment, conveyor and control panel

Suction compartment:

+ Designed with 4 opposite heat bars, divided into both upper and lower rigs.

+ There are fan parts to accelerate the heating process of the shrink film, heat dissipation and help cool quickly before going out

Conveyor:

The stainless-steel bars are connected to each other, moving the water bottles to cover the membrane from the inlet, passing through the suction chamber and taking out in just a few seconds.

Parameter adjustment table:

- Includes switch, conveyor speed adjustment button.

- Switch, temperature adjustment knob 2 separate heat rigs.

- Fan switch

Uses:

- Using the heat to make the shrinking film grip on the bottle

- The shrinking film is smooth, alike, not wrinkled

- Help to preserve water bottles better, not wet

Parameter of Heat shrink film machine - made in Vietnam

|

Model |

VAHS2000 |

|

Capacity (bottle / h) |

1000-2000 |

|

Electrical capacity (kw / h) |

12 |

|

Size (D * R * C mm) |

"1220x500x1500" |

|

Weight / kg) |

38 |

|

Price (USD) |

|

Notes when using 4-in-1 VACGF 2000 automatic bottle filling machine

+ VACGF2000 automatic bottle filling machine must use 380v power source. Therefore, if power consumption is not guaranteed, it will not guarantee the original capacity.

+ In the control panel, there is a LED screen showing the parameters you set on the machine as well as the actual operating capacity of the machine.

Under the Led screen on the control panel has a "Speed" button: This button is used to adjust the filling capacity of the machine. You can adjust the speed of operation of the machine by adjusting this button. However, the maximum capacity is 2000 PET bottles per hour.

+ To ensure maximum performance, you need to ensure the installation area. Viet An has designed the ground for the installation of sample VACGF2000 bottle filling machine for customers to consult.

Problems may be encountered when using the bottle filling machine VACGF2000

During operation, you may encounter some errors such as:

+ Stuck bottles

+ The amount of water extracted into the bottle does not guarantee the volume

+ The bottle cap is inverted, which leads to the bottle capping process not reaching its maximum performance.

Causes and ways to fix problems when encountered

Stuck Bottle: The main cause of bottlenecks can be caused by the improper filling of bottles. Incorrect mounting of mould size. This error is mainly caused by technicians having trouble installing.

The amount of water extracted into the bottle does not guarantee the right volume: The main reason is that the programming is not accurate or because you have installed the filling head in the wrong technique.

Bottlecap is overturned: This is an error when you pour the entire bottle cap into the container. However, because the manual lid tray does not have an air blower, push the cap down into the duct connected to the cap. To limit the flip of the bottle cap, you need to have a supervisor and correct operation.

To avoid this error, you can install an automatic bottle cap loading machine, but this solution is less chosen due to the high cost.

See more article details

Specifications of 4-in-1filling machine VACGF2000

|

A. VACGF2000 FILLING MACHINE - 4 STAGES MUST BE BUYED |

|

|

Model |

VACGF2000 |

|

Wash head |

12 |

|

Extraction head |

12 |

|

Head swirled |

1 |

|

Machine capacity (350ml bottle / h) |

1500-2000 |

|

Machine capacity (500ml bottle / h) |

1500-2000 |

|

Machine capacity (1500ml bottle / h) |

600-1000 |

|

Power capacity |

3.04 |

|

Pressure |

0.6-0.8MPA |

|

Bottle size |

Φ55-Φ100 |

|

Bottle height |

100-320 |

|

Electricity supply |

380v-50hz |

|

3 in 1 size |

3050*1100*1900 |

|

Weight |

1160 |

|

light inspection |

600*200*1000 |

|

Plastic conveyor |

6000 |

|

Price ( USD) |

|

|

B. SEPARATE PURCHASE STAGE INTEGRATED INTO A 4 IN 1 FILLING MACHINE- VACGF2000 |

|

|

Model |

Price ( USD) |

|

1. Bottle loading and arranging machine- VALS4000 |

|

|

2. Heat shrink film machine - VAHS2000 |

|

Hỏi đáp & đánh giá 2000-4 IN 1 AUTOMATIC BOTTLE FILLING MACHINE VACGF2000

0 đánh giá và hỏi đáp

Bạn có vấn đề cần tư vấn?

Gửi câu hỏi