Hotline

Vietnamese

Vietnamese  English

English  Laos

Laos  Cambodia

Cambodia  Thailand

Thailand  Indonesia

Indonesia  Philipins

Philipins  Myanmar

Myanmar

8000-6 IN 1 AUTOMATIC BOTTLE FILLING MACHINE VACGF8000

Contact

6-in-1 automatic bottle filling machine VACGF 8000 capacity of 8000 bottles / h

- Model: VACGF8000

- Capacity: 8000 bottles/h

- 1-year warranty

- Maintenance: Long-term

- Standard: ISO 9001:2015

- Free shipping-installation nationwide

Buy now

Free shipping

Request a consultation

Build your own plan

Order, advice 0949.41.41.41 - 0943.41.41.41 (7:30 - 21:00)

Category: FILLING-VACGF

Product code: VACGF8000

- Describe

- Parameters, configuration

- Picture

Product details

Automatic filling machines have a very important role in the food processing industry including bottled water production. Being improved and upgraded than the previous bottle extracting machines.

6-in-1 automatic Bottle Filling Machine VACGF8000 has many outstanding advantages, fast filling up to 8000 bottles per hour. If you are interested in the product of 6 bottles of automatic bottle filling machine with a capacity of 8000 bottles per hour - please contact Viet An at 0942 414141.

This type of industrial bottle filling machine is suitable for large capacity bottled water plants, that want to automate the production process. Products are being imported and installed in Vietnam and abroad.

6-in-1 automatic bottle filling machine VACGF8000 with a capacity of 8000 bottles 500ml

VACGF8000 belongs to the set of industrial automatic bottle filling machines imported, distributed, installed and manufactured by Viet An General Trading Joint Stock Company.

Viet An - the importer and distributor of Vietnam's filling machine

We are proud to be a unit specializing in importing and distributing filling machines, water purification lines, bottle blowing machines and producing the ice-making machine in Vietnam. Viet An has been constantly updating and applying the latest and most modern production technologies in the world in the products provided by Viet An to the market.

We are committed to all products provided by Viet An have a clear and genuine origin, ensuring quality standards with high durability and reasonable price.

The evidence for these commitments is the awards and certificates awarded by the party, State awarded and consumers voted.

Since Viet An officially introduced VACGF8000 6-in-1 automatic bottle filling machine, there have been many businesses, factories contacting to order and have positive feedback on this product. Let's join Viet An to learn more about the 6 in 1 automatic bottle filling machine VACGF8000 through the following article.

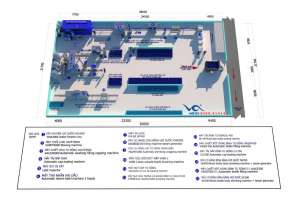

6-in-1 automatic bottle filling machine VACGF8000

ISO 9001:2015 standard

As like the automatic bottle filling machine VACGF2000, VACGF3000, VACGF5000 was born earlier. 6 in 1 automatic bottle filling machine VACGF8000 is manufactured according to the latest technology in the United States.

The whole process of manufacturing and assembling filling machines complies with the strictest international quality management system ISO 9001:2015.

Therefore, Viet An affirmed that the VACGF8000 bottle filling machine with 6 automatic stages is the most modern and best automatic filling machine in the market today.

6 automatic stages of bottle filling machine VACGF8000 provided by Viet An

Here are details of 6 automatic stages integrated into an automatic bottle filling line system VACGF8000. In addition, if there is a need, customers can choose to buy other automatic stages to integrate into this filling system.

Stage1: Air conveyors AC2

This is an extremely important stage in the filling line.

It is composed of a frame system of 304 stainless steel with a shiny surface, easy to clean and safe to use.

Use AC 2 gas to move the bottle automatically and quickly. gather bottles together without deforming bottles

Stage 2 + 3 + 4: Rinse wash-filling- 3 in 1 bottle capping

Rinse the bottle

- Meanwhile, the previous VACGF5000 model was only equipped with 14 washing head, the VACGF8000 series was equipped with a washing head system up to 18 heads.

- This machine will replace about 10 workers. Helping improve productivity, bring high economic efficiency, save maximum labour cost.

- The automatic bottle washing machine is designed with the ability to work sustainably, long term

- This type of washing machine with special design can be used to wash a variety of different shaped bottles. They can wash bottles of round necks, flattened necks and square necks. Therefore, enterprises can produce bottled drinking water with diversified shapes and designs.

- Water containers, frame and other components are made from 304 stainless steel, which helps the machine operate stably and long term. Life expectancy is much higher than other conventional washing machines on the market.

- When you want to change the bottles, you only need to change the Mold set of each corresponding bottle type. So you can wash different types of bottles without investing in buying a new washing machine like washing machines that apply old technology.

Principle of washing bottles:

Firstly 18 PET bottles will be transported by gear conveyors to 18 washing heads.

Here 18 bottles will be kept and turned upside-down by the bottle clamping parts.

When the bottle transported to the rinse head, the disinfecting water pump will rinse the bottle, after the bottle transported to the drying position, it will remove any remaining water from the bottle.

Then the bottle clamp is turned back and transferred to the gear conveyor to transfer the bottle to the next the filling cycle.

+ Automatic filling

Filling machine is designed with SUS # 304 material with high durability. No corrosion, no rust, suitable for a wet environment. Easy to clean, long use time.

After being washed at 18 washing heads, 18 bottles are transported to filling department by gear conveyor. In here, 18 bottles will be fixed by clamping parts transported to 18 filling heads. The water in the filling machine will be transferred into the bottle according to the set norms. The bottle is taken to the gear conveyor and moved to the next cap screw unit.

Filling capacity: 6000- 8000 bottles of 350ml, 6000- 8000 bottles of 500ml and 2000-2500 bottles of 1500ml

Bottle clamping unit: Designed very diverse, can be removed, replaced easily. When you want to fill the bottles with different volumes, you only need to remove and replace the bottle clamp parts in accordance with the bottle type. This creates flexibility in production.

Filling head: it is attached to the sensor, no further filling when reaching the set norm. And especially when there is no bottle, it will stop working to save fuel for production.

+ Automatic capping stage:

cap screw unit is designed with 6 screw heads made of steel and plated with a high grade 304 stainless steel. Helping ensure the absolute safety of food hygiene for the production of bottled drinking water. The machine can screw plastic caps and aluminium caps

You can adjust the vortex cap force, spin speed, conveyor speed easily

Principle of cap screw:

The gear conveyor will bring the filled PET bottles filled with water to the automatic bottle screw machine. The bottle clamping parts will fix the bottle position to 6 cap swirl heads. Bottle caps will be transported and swirled into bottles. Then the bottle clamping unit moves to the conveyor system to move to the next stage.

Bottle clamping unit: The bottle capping machine is designed to be very flexible. Can be removed easily. When you want to change the size of the bottle to twist the cap, simply remove the bottle clamping parts and replace it with the bottle clamping parts compatible with the bottle you want.

Cap capacity: 8000 caps per hour. So to ensure productivity, the vortex machine will be attached to the automatic bottle cap loading machine.

Stage 5: Automatic bottle cap loading machine

The machine includes 1 tray containing cap, 1 system of conveyor motor, 1 conveyor, 1 air blowing system and 1 magic induction eye. With conveyor motor system automatically corrects the bottle cap when inverted to ensure 100% of air blowing in is correct

The magic induction eye system is automatically inserted and filled, the system automatically disconnects when full caps to help the operator much simpler during use.

Principle of operation

The bottle cap is delivered to the tray containing the cap of the machine. The motor system operates, conveyors bring the bottle cap to the auto-screw vortex via the duct.

The cap loading machine is attached with a sensor with the magic eye so make sure to always move the bottle cap in the right direction, fast, high capacity.

The induction magic eye system automatically puts the cap on when the cap is missing and automatically disconnects when the cap is full.

Stage 6. light inspection

light inspection is made from SUS304 stainless steel frame with an internal control panel containing touch lights.

Principle of operation

Select the bottle probability to pass through the light inspection. With lights to help look and detect a strange object in a bottle(if available).

This is a necessary step to ensure food hygiene and safety factor in bottled water production

Plastic conveyor system

The conveyor is a part that connects stages together. Help to move bottles quickly and save space. They help replace many workers.

The frame of the plastic conveyor is made of high quality 304 stainless steel material. Shiny, easy to clean, long life.

With 6 automatic stages integrated into the VACGF8000 model, this product is being launched by Vietnam An at an attractive price.

Automatic stage (purchase separately)

In addition to the above 6 mandatory automatic stages of automatic bottle filling machine VACGF8000, customers can invest in a number of other types of machines to save labour costs, increase productivity.

1. Semi-automatic Bottle loading and bottles arrange machine

With a tray containing a large plastic bottle, each work shift needs only to pour 1 to 2 times the bottle shell into the tray of the loading machine and the bottle

The machine will automatically put the bottle and arrange the bottle in the right direction

With a working capacity of 2000 to 4000 bottles per hour, it is much higher if using normal labour

Specification of Bottle loading and bottles arrange machine

|

Model |

VALS4000 |

|

Machine capacity (BPH) |

2000-4000 |

|

Bottle type-2 mould (ml) |

300-1500 |

|

Electrical capacity (kW / h) |

0.75 |

|

Size (D * R * C mm) |

1200X1500X900 |

|

Weight / kg) |

150 |

|

Price (USD) |

|

2. Bottle dry blow machine -AD10000:

Uses: Blow dry bottles before packaging

The whole machine frame, blowing head system is made of stainless steel material

The air duct system on the blow heads helps to blow dry bottles quickly

Specifications of the Bottle dry blow machine

|

Model |

VAD10000 |

|

Machine capacity (bottle/h) |

4000-8000 |

|

Electrical capacity (kW/h) |

6 |

|

Size (D*R*Cmm) |

1370*800*1500 |

|

Weight (Kg) |

190 |

|

Price (USD) |

|

3. head label drop machine-VAL9000:

Uses: Automatically drop labels into bottles with two drop labels

With the most modern label drop technology application in 2021, it helps to pass the label drop process quickly and accurately.

There are drop labels on the control panel of the device for easy observation by the manufacturer. Speed drop to 6000-9000 labels per hour

Parameter Double-head label drop machine

|

Model |

VAL9000 |

|

Capacity (bottle / h) |

6000-9000 |

|

Electrical capacity (kW / h) |

4 |

|

Suitable bottle diameter (mm) |

Φ28-Φ125 |

|

Suitable label length (mm) |

30-250 |

|

Suitable label thickness (mm) |

0.03-0.13 |

|

Suitable internal diameter |

5"-10" |

|

Size (D * R * C mm) |

3200*1200*2100 |

|

Weight / kg) |

600 |

|

Price (USD) |

|

4. Automatic rotary labelling machine to label the round bottle with opp label and hot melt glue: VAR9000.

Uses: Label the bottle automatically

The reason you should use automatic labelling machine:

- Labelling speed is much higher than manual labelling

- The quality of the sticker is uniform, not wrinkled, no damage to the label, the sticker is not torn

- Save time labelling

- Saving labour costs

- Increasing competitiveness

Specifications Automatic rotary labelling machine for labelling round bottles

|

Model |

VAR9000 |

|

Capacity (bottle / h) |

6000-9000 |

|

Suitable bottle diameter (mm) |

Φ28-Φ125 |

|

Suitable label length (mm) |

30-250 |

|

Suitable label thickness (mm) |

0.03-0.13 |

|

Suitable internal diameter |

5"-10" |

|

Size (D * R * C mm) |

2400*2300*2100 |

|

Weight / kg) |

1,200 |

|

Price (USD) |

|

- Steam bottle shrinking machine: VAS9000

Use steam to shrink the bottle, help shrink film quickly and beautifully.

Technical specifications of Steam bottle shrinking machine

|

Model |

VAS9000 |

|

Capacity (bottle / h) |

5000-9000 |

|

Electrical capacity (kW / h) |

18 |

|

Size (D * R * C mm) |

1800*500*1700 |

|

Weight / kg) |

150 |

| Price(USD) |

|

- Inkjet printer

The machine helps print faster, more beautiful use.

With a modern design, advanced inkjet technology makes the printing process faster. The printing mould does not need to contact the printing surface.

Print on most surfaces, including curved surfaces such as bottles and jars

Inkjet printer parameters

|

Model |

VA22000 |

|

Maximum print line |

3 |

|

Electricity supply |

240V |

|

Size (D * R * C mm) |

400*320*527 |

|

Weight / kg) |

27 |

|

Price (USD) |

|

7. Automatic log shrinkage machine: VAGM10000

Specially used to produce products for drinking water, soft drinks ... close log 6 -12 -24 bottles automatically.

It works with small noise, large capacity

Each hour can be up to 10 thousand bottles per hour

Parameter Automatic log shrinkage machine

|

Model |

VAGM10000 |

|

Capacity (bottle / h, log 24 bottles of 500ml) |

9000-11000 |

|

Electrical capacity (kW / h) |

21 |

|

Size (D * R * C mm) |

5550*3700*2100 |

|

Weight / kg) |

870 |

|

Price (USD) |

|

See more article details

Specifications of automatic filling machine VACGF8000

|

A. VACGF8000 FILLING MACHINE - 6 STAGES MUST BE BUYED

|

|

|

Model |

VACGF8000 |

|

Wash head |

18 |

|

Extraction head |

18 |

|

Head swirled |

6 |

|

Machine capacity (350ml bottle / h) |

5000-8000 |

|

Machine capacity (500ml bottle / h) |

5000-8000 |

|

Machine capacity (1500ml bottle / h) |

2000-2500 |

|

Power capacity |

3.5 |

|

Pressure |

0.6-0.8MPA |

|

Bottle size |

Φ55-Φ100 |

|

Bottle height |

100-320 |

|

Electricity supply |

380v-50hz |

|

3 in 1 size |

2300*1700*2400 |

|

Weight |

2500 |

|

Air conveyor |

5000*220*1000 |

|

Bottle cap loading (D*R*Cmm) |

1200*950*3000 |

|

light inspection |

600*200*1000 |

|

Plastic conveyor |

15000*160 |

|

Price (USD) |

|

|

B. SEPARATE PURCHASE STAGE INTEGRATED INTO A 6 IN 1 FILLING MACHINE – VACGF8000 |

|

|

Model |

Price (USD) |

|

1. Semi-automatic Bottle loading and bottles arrange machine VALS4000 |

|

|

2. Bottle blowing machine - VAD10000 |

|

|

3. Double-headed label drop machine - VAL9000 |

|

|

4. Automatic rotary labelling machine for labelling round bottles with opp labels and hot melt glue stick - VAR9000 |

|

|

5. Steam bottle shrink machine - VAS9000 |

|

|

6. Inkjet printer - VA22000 |

|

|

7. Automatic log shrinkage machine: VAGM10000 |

|

Hỏi đáp & đánh giá 8000-6 IN 1 AUTOMATIC BOTTLE FILLING MACHINE VACGF8000

0 đánh giá và hỏi đáp

Bạn có vấn đề cần tư vấn?

Gửi câu hỏi