Hotline

Vietnamese

Vietnamese  English

English  Laos

Laos  Cambodia

Cambodia  Thailand

Thailand  Indonesia

Indonesia  Philipins

Philipins  Myanmar

Myanmar

VAQGF150-L 3 in 1 Automatic Bottle Filling Machine VAQGF150-L

Contact

3 in 1 Automatic bottle filling machine VAQGF150 -L

- Capacity: 150 large necked bottles with 20 liters per hour

- Origin: Genuine

- Warranty 12 months

- Free shipping-installation nationwide

Buy now

Free shipping

Request a consultation

Build your own plan

Order, advice 0949.41.41.41 - 0943.41.41.41 (7:30 - 21:00)

Category: FILLING-VAQGF

Product code: VAQGF150-L

- Describe

- Parameters, configuration

- Picture

Product details

3-in-1 automatic bottle filling machine VAQGF 150-L of Viet An is currently the most advanced automatic filling machine. Specialized for washing, pouring water into the bottle and closing the lid to the big neck threaded bottle.

With the application of the most modern scouring, filling and capping technology in the United States, the VAQGF 150-L will be an effective support for bottled pure water business and production facilities today.

3 in 1 automatic big neck threaded bottle filling machine VAQGF 150-L

This is the most advanced 3-in-1 automatic filling machine on the market today

The machine is manufactured on modern technological line, quality standard ISO 9001:2015

All components constituting the machine are genuine, high quality

The device is integrated with 3 functions: automatic inner and outer washing, automatic filling of water bottles and automatic closing of the bottles.

With a capacity of 150 jar of 20 litres, a large necked threaded jar an hour, model VAQGF150-L will help businesses save 3-5 employees, reduce production costs, increase competitiveness for businesses. and automation in the production of bottled water.

Benefits when using the 3 in 1 automatic bottled bottle filling machine VAQGF150-L

- Improve production capacity of bottled pure water

- Automating the production process

- It is suitable for modern manufacturing trends

- Saving production costs, increasing competitiveness for businesses

- Ensuring food safety and hygiene for big round 20L round neck jars

- Update new production technologies into bottled water production activities

- Reducing labour and cost savings

VAQGF150-L 20L big neck threaded bottle filling machine with 3 automatic stages

Stage 1: Automatic bottle rinse

20L big neck threaded jar shells are individually transferred to the bottle holder of the washer, filling and capping of the VAQGF150-L.

With structure includes:

- Jar chain conveyor system to hold the jar-head, moving the jar.

- Conveyor motor system to operate the conveyor chain system.

- 304 stainless steel head booster pump system to create pressure to pump both pure water and sterilized ozone to the bottom of the water tank through the washing heads.

20L big neck threaded jars will be washed inside and out clean with pure water and sterilized ozone, so make sure that the cover is clean as new and completely sterile before giving to the filling heads.

The whole process of washing in and out of the bottle takes place automatically at a rate of 150 jars of 20L / h.

Stage 2: filling water into the bottle automatically

Model VAQGF 150-L is designed with 1 filling head. This filling head is made of high quality 304 stainless steel. Operates under pressure 0.45-0.6 Mpa. Plumbing system to bring purified water from the source to the filling head. At the top of the filling head, there is an induction system to automatically fill the jar with and without filling. This helps to save the maximum amount of pure water.

After being filled with water, the jar will be transferred to the top of the lid to close the lid

Stage 3. Close the lid automatically

Model VAQGF 150-L has 1 closed capping. When the jar is filled with water, it is transferred to the capping head, and the cap feeder tube puts the cap into the jar and the cap with a pressure of 0.45-0.6 Mpa will close the lid to the jar with 100% accuracy.

To ensure that the lid does not tip up during the cap feeding process, you should invest in an automatic cap loader

In addition to model VAQGF150-L, Viet An also provides a lot of other bottles and automatic bottle filling machines. Customers can refer here: https://vietan.vn/may-chiet-rot

Suggesting 5 other automatic steps to integrate with VAQGF150-L filling machine to create a fully automatic filling line

The automatic big threaded bottling filling machine VAQGF150-L is an extremely modern machine. They are easily compatible with other machines to create a fully automated, closed production process.

Viet An offers 5 suggestions for customers to choose installation investment.

- BS-1 semi-automatic decapping inside and outside bottle brushing machine

BS-1 Decapping inside and outside bottle brushing machine

The BS-1decapping inside and outside bottle brushing machine is a great solution for bottled water enterprises. With reasonable investment costs, high performance, saving labour costs.

The machine is equipped with 1 decapping cap, a brush chamber. Machine control system. The brush chamber has a brush system. 304 stainless steel head booster pump system.

The machine is connected to a power source, using air pressure to remove the lid

Workers upside down the jar need to be removed to the position to withdraw. Click on the pedal switch mounted on foot machine. Under the action of the withdrawal cylinder, the cap will be removed from the jar and dropped down the slide into the position where the lid will be placed for reuse.

The jar shells, after being removed, will be placed over the bottle. Now the booster pump works, pumping water into the brush chamber, the bristles moving clockwise brushing the entire body of the jar. Under the action of the brush, the brush also moves. The bottle shell will be thoroughly washed, clean.

Customers can use the tap water, sewage of the RO filter system to supply internal and external washing decapping and remove the BS-1 bottle cap to save water, save costs.

Specifications of BS-1 semi-automatic decapping inside and outside bottle brushing machine

|

Model |

BS1 |

|

Capacity (jar / h) |

150-200 |

|

Wash head |

1 |

|

Electricity supply |

1.1kw |

|

Pressure (Mpa) |

0.45-0.6 |

|

Dimensions (LxWxH) |

770x800x1150 |

|

Weight / kg) |

40 |

|

Price (USD) |

|

2. Light inspection (DJ-100)

Uses: Screening to see if there are strangle objects or not

Usage: Workers will select the probability of the water bottle after production through this DJ-100 light inspection. Under the light of the machine, workers will see clearly whether the water jar is abnormal or not. And workers proceed to remove unqualified jars. This helps improve the reputation of the business

- Shrinking machine steam generator (SK-300)

This steam bottle shrink machine is an essential device for businesses that produce bottled pure water.

Structure: 1 boiler and 1 shrinkage chamber

Operating procedure of the machine. Water is supply into the steam tank, the boiler is connected to a power source to heat water up, creating steam to supply the contraction chamber. The bottles filled with water were picked up by polymer workers through the SK-300 shrinking chamber. Under the heat of the steam will deform the shrink film, shrinking the membrane tightly. Smooth, smooth surface, no wrinkles.

Specifications of Shrinking machine steam generator (SK-300)

|

Model |

SK-300 |

|

Capacity (jar / h) |

100-300 |

|

Power(kw) |

18 |

|

Size (DxRxCmm) |

1500x550x800 |

|

Price (USD) |

|

- heat bottle shrinking machine (SK-300E)

Structure: Thermal chamber and shrinking chamber.

The machine is connected to a power source, the heating chamber will supply heat to the contraction chamber. The polymer films taken by workers on the whole body of the bottle will go through the shrinking chamber. Under the heat of the shrinking chamber, temperature deforms the membrane, covering the entire body of the flask smoothly.

With extremely intelligent design, can automatically adjust the temperature and keep a stable temperature for the shrinkage chamber. Therefore, the quality of shrink film always ensures beautiful and smooth

Technical specifications of heat bottle shrinking machine SK-300E

|

Model |

SK-300E |

|

Capacity (jar / h) |

100-300 |

|

Power(kw) |

18 |

|

Size (DxRxCmm) |

|

|

Price (USD) |

|

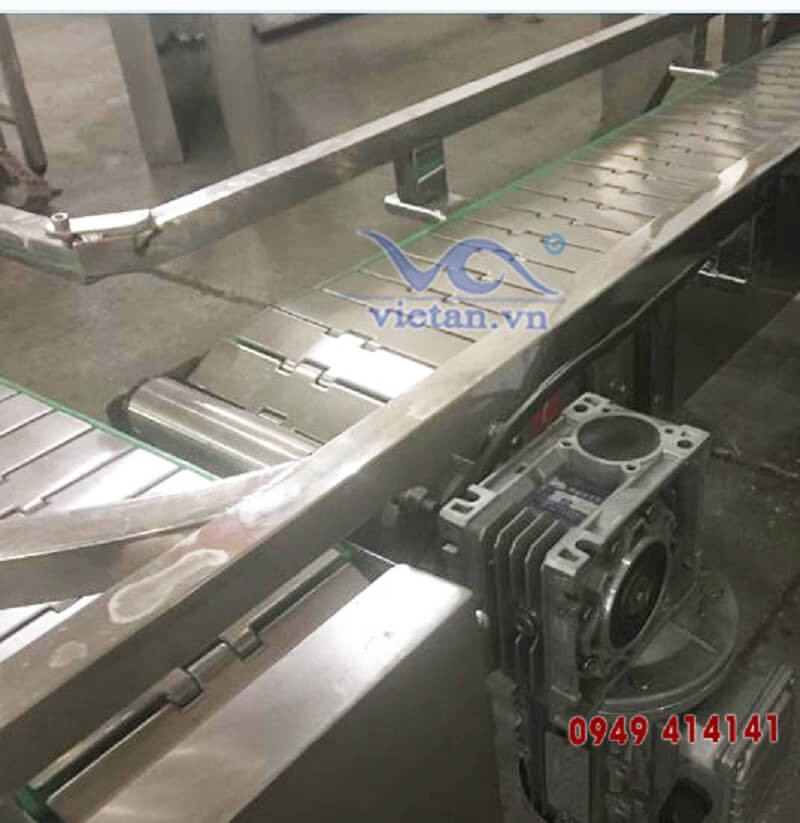

- Stainless steel conveyor for water jar containing CSSG-4

To connect the automatic stages together and to transport the jar after it has been filled quickly, you should invest in installing this 304 stainless steel conveyor system.

With dimensions of 4 meters in length and 29 cm in width. The loading capacity of stainless steel conveyor is very high, can transport water bottles fast, with durability over 20 years

Technical specifications of Stainless steel conveyor

|

Capacity (jar / h) |

CSSG-4 |

|

Power(kw) |

0.75 |

|

Size (DxRxCmm) |

4000x290 |

|

Price (USD) |

3.390 |

VAQGF150-L automatic large neck bottle filling machine with modern production models

Automate production

We are living in an age of industrialization and modernization of the country. With the strong development of the industry. Therefore, the application of scientific and technological advances to production is a vital element of enterprises in the new era. VAQGF150-L automatic washing, filling and capping machine integrates 3 automatic functions, operating continuously without labour. This bottle filling machine will help bottled beverage manufacturers automate production to match the modern trend

High productivity

With the old technology line of semi-automatic machines, the process of washing, extracting and closing the bottles requires a lot of labour but the productivity is very low.

The 3-in-1 VAQGF150-L is completely different. The machine will automatically wash the bottle, pour the water into the jar and close the jar of the manufacturer's job just to ensure the bottle shell, pure water supply and cap enough quantity for the machine to operate. The performance of the machine is up to 150 jars large neck threaded 20L/h.

Simple and easy operation process

VAQGF150-L 3 in 1 automatic bottle filling machine has an extremely intelligent control system. They can be automatically disconnected when something goes wrong so absolutely safe for production activities.

The control buttons, adjust the operating speed of the machine, the PLC touch screen fully displays the operating parameters of the machine so that the operator can monitor and supervise.

You only need to install once after the automatic operation. The operation will be instructed in detail by Viet An technician for customers when the installation is completed

Genuine machine, good quality

Model VAQGF150-L belongs to a 3 in 1 automatic bottle filling and pouring product series supplied by Viet An to the market. All components constituting the machine are genuine, with high durability. The origin of the device is fully and clearly recorded so that customers can check

The machine is manufactured according to ISO 9001:2015, the most stringent standard today.

If customers use properly, regularly clean the machine, periodic maintenance, the machine can be used for more than 20 years.

Increasing competitiveness for businesses

The VAQGF150-L machine can replace 3-5 workers. So, on average, you can save from 21 million VND to 35 million VND per month on labour costs. From there, businesses can lower the cost of water bottles to compete with other businesses while ensuring profit.

In addition, this is the most modern machine line of washing, filling and capping technology in 2019, applying the most energy-saving technology in the production process. The machine can operate continuously for a long time. This will help businesses have an advantage over other units using the old technology filling line

See more article details

Specifications of 3 in 1 Automatic jar filling machine VAQGF150 (Must be buyed)

- 20l JAR FILLING MACHINE VAQGF150-L – 3 STAGES MUST BE BUYED

|

Model |

VAQGF150-L |

|

Extraction head |

120-150 |

|

Head swirled |

1 |

|

Power capacity (kw/h) |

2 |

|

Pressure (Mpa) |

0.45-0.6 |

|

size (D*R*Cmm) |

3500x700x1700 |

|

Weight (Kg) |

260 |

|

Price (USD) |

|

2. SEPARATE PURCHASE STAGE INTEGRATED INTO A 3 IN 1 JAR FILLING MACHINE VAQGF150-L

|

Model |

Price (USD) |

|

1. BS-1 Decapping inside and outside bottle brushing machine |

|

|

2. DJ-100 light inspection |

|

|

3. SK-300 Shrinking machine steam generator |

|

|

4. SK-300E heat bottle shrinking machine |

|

|

5. CSSG-4 Stainless steel conveyor for water tank containing |

|

Hỏi đáp & đánh giá VAQGF150-L 3 in 1 Automatic Bottle Filling Machine VAQGF150-L

0 đánh giá và hỏi đáp

Bạn có vấn đề cần tư vấn?

Gửi câu hỏi